İd Large Area Formwork System

The large area wall formwork consists of H20 wooden beams, wall braces made of steel M 10, plywood and accessories. The surfaces of the H20 beams, which are fixed to the steel wall braces by means of connection hooks, are covered with plywood. As a result a panel with the desired sizes is obtained, which can be assembled with mobile cranes. With these large-sized panels the desired heights can be obtained at one time. The order of the assembly procedures are: the steel wall braces are places with certain distances according to the concrete load. The H20 beams are fixed to the braces in a way that the plywood cannot bend. The plywood, which is cut according to the desired panel size, is assembled to the surface of the H20 beams by means of wooden screws. The vertical alignment of the formworks is ensured with push-pull supports and the concrete pressure is borne by 17 mm tie-rods and their wing nuts. The anchoring sets have a traction load capacity of 16 tons and the safety coefficient of 2,5 is taken into consideration and calculated as maximum 6,4 tons during the formwork design. These formworks, which are assembled by means of a mobile crane, cover large areas with only a few workers in one go as they are made of large components. Procedures such as casting the concrete or holding the vibrator are carried out on the working platform, which is assembled to the formwork beforehand.

Large Area Circular Wall Formwork

In contrast to the large area flat wall formworks the circular wall formworks are obtained with form elements, which are placed between the H20 beams and the plywood. Circular wall formworks can be assembled with a very simple and economic solution by using wooden circular form elements, which are cut according to the radius measure of the project and mobile brace connecting parts.

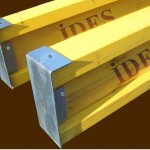

Large Area Column Formwork

The large column formworks consist of H 20 / plywood, L-shaped steel wall braces or flat steel braces and can be adjusted according to usage. They can be assembled easily by means of a crane. The formwork is mounted by struts. It is closed by connecting the moving outer corner fasteners to the two diagonal corners. The concrete pressure is borne by tie-rods, wing nuts and steel bracings. If no holes are desired in the column, then the request is met by increasing the number of bracings. The L-bracing can be assembled and reassembled up to 15 cm and the column sections can be changed up to 20 cm without affecting the assembly. In adjustable columns, by means of the brace connecting corner element, which is fixed to the flat steel braces, a column formwork with a 120 cm x 120 cm section can be turned into a column formwork with a 30 x 30 cm section.